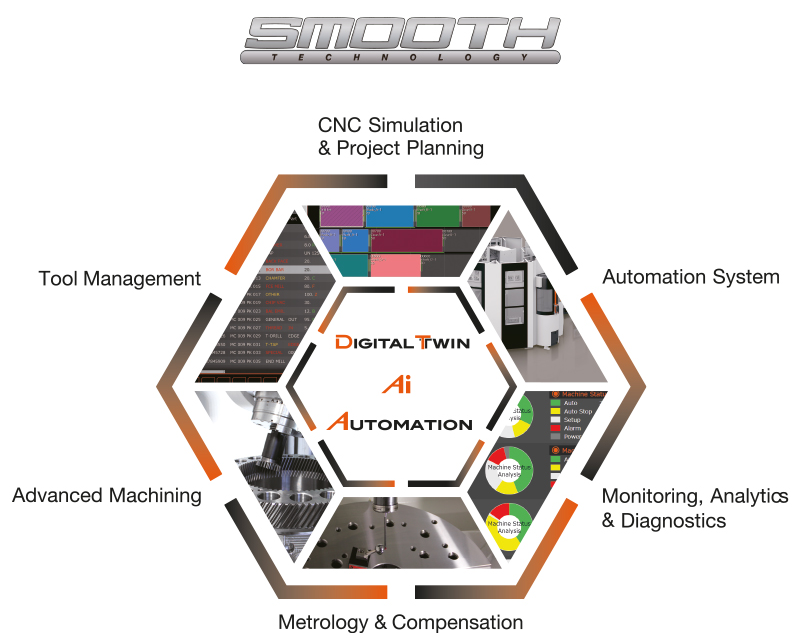

Total support for IoT and Ai digitalised factory network

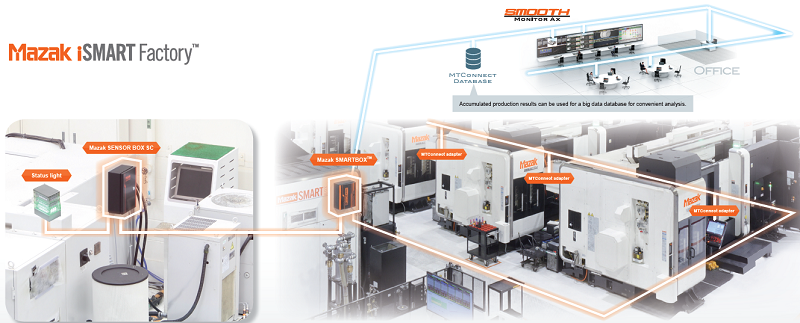

Companies are increasingly looking towards IoT and AI technologies as investments to increase production efficiency. By collecting and analyzing big data, production can be optimized and production quality can be improved. However, digitalization and networking are frequently regarded as difficult and expensive. Yamazaki Mazak has begun digitalization and networking of its own factories to maximize production efficiency over many years.

Our first Mazak iSMART Factory™ pilot was started at our facility in Kentucky in the United States in 2015. Since then, we have continued to expand the concept, first to our global headquarters in Oguchi in early 2017 and then at our Singapore factory in June 2017. Mazak Inabe Plant became operational in 2018. Our latest Mazak iSMART Factory™, Worcester facility would be upgraded to iSMART Factory™ status, the company’s highest level of Industry 4.0 connectivity, in line with its other plants in Japan and Kentucky in the United States. Using this expertise, we have developed products and software that will make your production smart.

Mazak iSMART FactoryTM Solution

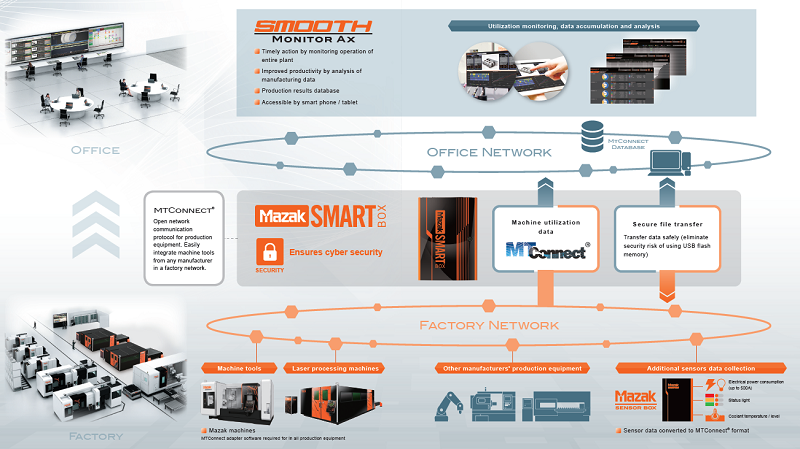

Data collection, utilization and analysis

View enlarged image

MAZAK SMARTBOXTM

Smart Boxes for smart businesses

Using MTConnect as the foundation, the MAZAK SMARTBOXTM connectivity of machines and other production equipment provides enhanced monitoring and analytical capabilities including advanced cybersecurity protection.

Data gathering and analysis resulting in improved productivity and efficient factory management.

Mazak smart box is specially designed for IoT by preventing unauthorized access.

SECURITY

- Provides advanced cybersecurity protection by a state-of-the-art Cisco networking platform and Layer3 Managed Switch industrialised for the factory environment.

ANALYTICS

- Provides insight from the utilisation of individual machines, to entire manufacturing cells.

- Open standard provides the freedom to choose any third-party analytical software platforms software.

- Utilises FOG computing concept created by Cisco; extending cloud computing to the edge of an enterprise’s network. Also known as Edge Computing.

MONITORING

- Monitors data from any machine regardless of manufacturer, age and CNC.

- Yields higher throughput increased utilisation and lowered downtime.

MAZAK SENSOR BOX

Sensor data converted to MTConnect format

The data collected by the Mazak SENSOR BOX is converted to the MTConnect format.

Three types of Sensor box:

- SC is used to obtain data from a machine status light and coolant temperature, level

- S is used to obtain data from a machine status light

- E is used for electrical power consumption data

Smooth Technology

Click here to find out more information