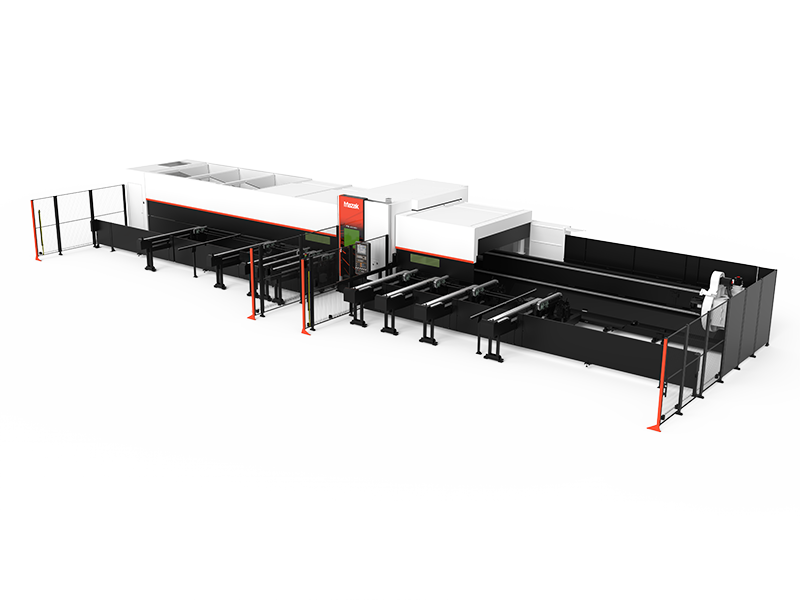

FG-400 NEO

3D Fiber Laser cutting machine for long pipes and structural materials

The FG-400 NEO is designed for high-speed 3D cutting of long tube, pipe and structural material.

Featuring a variety of advanced technologies, the FG-400 NEO offers operability and flexibility that underpin high-efficiency cutting.

The unique Beam Shaping Technology automatically adjusts the beam diameter and energy concentration to ensure the best possible result on various materials and thicknesses

Exceptional productivity results from the combination of the laser machine’s fiber resonator, and the capacity to perform multiple processes including cutting, drilling, tapping. The FG-400 NEO is an ideal option for manufacturers looking to make a step-change in their tube laser processing capabilities.

Key features:

- Beam shape and diameter control improves cut speed and cut quality of various materials and thicknesses

- The 3D cutting head with A-axis and B-axis can process a broader range of materials at any desired angle

- 4 chucks system gives greater processing stability and high accuracy cutting by preventing material distortion during processing

- Run multiple processes in one machine, from 3D cutting to tapping, when equipped with the optional tapping unit

- Low running cost thanks to fiber technology

- Equipped with the cutting-edge Mazak FX control with 15” screen, includes integrated tech tables that simplify operation

- Available in 4.0 kW Fiber laser resonator configuration

Visit our new FG-400 NEO landing page here

Machine Specifications

| 4.0 kW Laser | Values | |

|---|---|---|

| Square pipe | Channel type L-steel | 20 x 20 to 254 x 254 mm |

| H-steel / L-steel | 20 x 20 to 305 x 305 mm | |

| Min. length of remaining material | Reclamping | 0 |

| Chopping off | 355 | |

| Height of chuck center | 1,200 | |

| Axis Travel | X-axis | 8790 |

| U-axis | 2515 | |

| V-axis | 9300 | |

| Y-axis | 1,270 | |

| Z-axis | 425 | |

| A-axis | +/- 99999.999 | |

| B-axis | +/- 135 | |

| C-axis | +/- 99999.999 | |

| Rapid traverse | X/U/V-axis | 60 m/min |

| Y-axis | 36 m/min | |

| Z-axis | 30 m/min | |

| A-axis | 9,600 °/min | |

| B-axis | 9,600 °/min | |

| C-axis | 17,400 °/min | |

| Machine Specification | Axis Drive System | AC servomotor, X/X2/X3: Rack & pinion Y/Z:-axis: Ball screw |

| Positioning accuracy | X/X2/X3 axis: +/-0.05/500 & Y,Z axis: +/-0.01/500) | |

| Repeatability | X/X2/X3/Y/Z : +/- 0.1 mm & A/B : +/- 0.1 deg | |

| Cutting head | 3D torch L140 with protective windows and Protection function | |

| Profiling unit | Non-contact type | |

| Lighting Unit | LED lamp | |

| Oscillation Indicator | Yellow (ready for laser oscillation) Red (laser beam is emitted) | |

| Assist gas switching | 3 (Oxygen, air, and assist gas) | |

| Assist gas switching | 0.99 (Oxygen), 0.83 (Air), 3.0 (Assist gas) | |

| Assist gas pressure NC function control | Assist gas pressure can be programmed. Max. setting: 2.5 MPa. | |

| Mass (kg) | 38500 | |

| Laser output adaptive control | Laser output can be adapted to the actual feed | |

| Noise Level (dBA) | Less than 80 | |

| Workpiece loading length (m) | for 8m machine : 8080 mm | |

| Workpiece unloading length (m) | for 8m machine : 8000 mm | |

| AXIS TRAVEL : X-axis (loading) | 8790 mm | |

| Laser Resonator Specifications | Laser type | Fiber laser |

| Wave length | 1060 to 1080 nm | |

| Oscillation mode, configuration | Pomp diodes and active Fiber | |

| Continuous rated output | 4 kW | |

| Output range | 200 to 4000 W | |

| Pulse mode | Minimum 20µs | |

| Pulse frequency Pulse duty | 1 Hz to less than 500Hz - 0 to 100% 500Hz to 1 kHz - 2 to 100% | |

| Beam mode | Variable by Beam Shaping Mode | |

| Output stability | ±1.0% | |

| Laser gas | None | |

| Mixture rate of laser gases | No gas | |

| Gas consumption amount | 0 l/min | |

| Beam shutter | Inside laser resonator | |

| Chiller System | Reservoir | 70 L |

| Circuit cooled | Laser and optics | |

| Control Specifications | Name | SmoothTUBE |

| CPU | 64 bit | |

| Input method | Touch Panel, or data input via USB memory device | |

| Monitor | 21.5" wide full HD monitor, dual monitor | |

| Control method | Semi-closed loop | |

| Memory Capacity | 8 MB | |

| Program Storage Capacity | 1000 programs | |

| Programming method | EIA/ISO method | |

| Program number | 4-digit number for program identification | |

| Number of controlled Axes (18-axis control) | Loader/Unloader | |

| Minimum setting unit | 0.0001 mm | |

| Servo System | Digital servo system | |

| Position detector | Encoder | |

| Input Interface | USB 2.0 x 2 ports | |