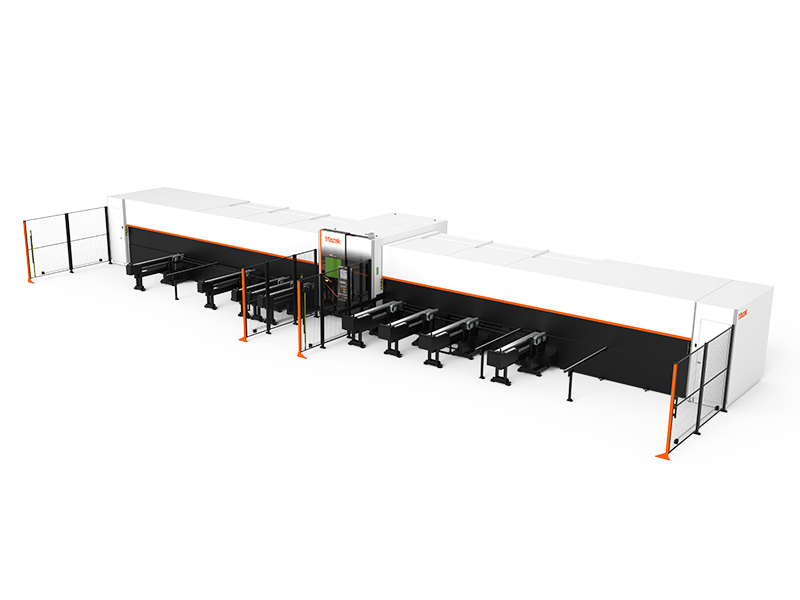

FG-220

Precision 3D Fiber Laser cutting of long pipes and structural materials

The FG-220 is designed for precision 3D cutting of long tubes (with round, square, rectangular, and triangular cross-sections) and structural materials (such as I and H beams, angle iron, and additional user-defined shapes).

Exceptional productivity results from the combination of the laser machine’s fiber resonator and the capacity to perform multiple processes including cutting, drilling, tapping, which leads to significantly reduced in-process times.

Mazak’s proprietary 3D laser cutting head with an extended range of movement across an A-and a B-axis expands on the array of possible applications. The FG-220 enables machining at any desired angle and from various directions, thus achieving even complex shapes, as well as tight joint-fits.

Key features:

- The 3D cutting head with A-axis and B-axis can process a broader range of materials at any desired angle.

- 4 chucks system gives greater processing stability and high accuracy cutting by preventing material distortion during processing.

- Run multiple processes in one machine, from 3D cutting to tapping, when equipped with the optional tapping unit.

- Low running cost thanks to fiber technology

- Equipped with the advanced Mazak FX control with 15” screen, includes integrated tech tables that simplify operation.

- Available in 4 kW Fiber laser resonator configuration.

Machine Specifications

| 4.0 kW Laser | Values | |

|---|---|---|

| Maximum machining dimensions | Round pipe | Ф20 to Ф 220 |

| Square pipe | 20 x 20 to 152.4 x 152.4 | |

| Channel type L-steel | 20 x 20 to 152.4 x 152.4 | |

| H-steel / L-steel | 20 x 20 to 152.4 x 152.4 | |

| Min. length of remaining material | Reclamping | 0 mm |

| Chopping off | 325 mm | |

| Height of chuck center (mm) | 950 mm | |

| Axis Travel | X-axis | 7155mm-13255mm |

| U-axis | 3989mm-13189mm | |

| V-axis | 2,315 mm | |

| Y-axis | 985 mm | |

| Z-axis | 370 mm | |

| A-axis | 99999.999 deg | |

| B-axis | +/- 135 deg | |

| C-axis | 99999.999 deg | |

| Rapid traverse | X/U/V-axis | 100 m/min |

| Y-axis | 36 m/min | |

| Z-axis | 30 m/min | |

| A-axis | 9,600 °/min | |

| B-axis | 9,600 °/min | |

| C-axis | 20,000 °/min | |

| Machine Specification | Axis Drive System | X/U/V-axis Rack & pinion. Y/Z-axs- Ball screw |

| Positioning accuracy (mm) | X/U/V-axis: +/- 0.05/500 Y/Z-axis: +/- 0.01/500 | |

| Repeatability | X/U/V-axis: +/- 0.01 mm Y/Z-axis: +/- 0.01 mm A/B-axis: +/- 0.01 deg | |

| Cutting head | 3D torch (L120 type) | |

| Profiling unit | Non-contact type | |

| Lighting Unit | LED lamp | |

| Oscillation Indicator | Yellow signal lamp (laser high voltage ON) Red signal lamp (shutter open) | |

| Assist gas switching | 3 gas types, Set pressure: 0.03 to 2.5 MPa | |

| Assist gas switching | Supply pressure: 0.78 MPa (Oxygen), ), 0.83 MPa (air) 3.0 MPa (addist gas) | |

| Assist gas pressure NC function control | Assist gas pressure can be programmed directly Max. setting: 2.5 Mpa | |

| Mass (kg) | 40,400 kg | |

| Laser output adaptive control | Laser output can be adapted to the actual feed | |

| Noise Level (dBA) | Max.80 dBA | |

| AXIS TRAVEL : X-axis (loading) | 7155mm(6m)/9055mm(8m)/13255mm(12m) | |

| AXIS TRAVEL : U-axis (unloading) | 3989mm(3m)/7089mm(6m)/8989mm(8m)/13189mm(12m) | |

| Laser Resonator Specifications | Laser type | Fiber laser |

| Wave length | 1060 to 1080nm | |

| Continuous rated output | 4 kW | |

| Output range | 400 to 4000W | |

| Pulse frequency Pulse duty | 1 Hz to less than 1 kHz - 0 to 100% 1 kHz to 2 kHz - 20 to 100% | |

| Control Specifications | Name | MAZAK FX (30i-L5) |

| CPU | 64 bit | |

| Input method | MDI key input or USB | |

| Monitor | 15 | |

| Control method | Semi-closed loop | |

| Memory Capacity | 2MB | |

| Program Storage Capacity | 1000 programs | |

| Programming method | EIA/ISO method | |

| Program number | 4 digits each | |

| Number of controlled Axes (14-axis control) | 14-axis control | |

| Number of controlled Axes (18-axis control) | 18-axis control | |

| Minimum setting unit | 0.001 mm | |

| Servo System | Digital | |

| Position detector | Encoder | |

| Input Interface | USB | |