TA Series

The TA (turn-assist) series is an easy-to-operate robot cell integrated with Mazak’s Smooth CNC, ideal for small to medium lot sizes. With an automated robot arm for loading and unloading of workpieces, the TA is ideal for applications that require lights out unmanned running overnight or at weekends. Both the machine tool and the robot are controlled from the Mazak Smooth CNC, which provides a seamless interface and extremely fast set-up.

Main Benefits

- Affordable automation

- Fast and easy set-up for a new job

- Proven system - Many similar systems installed

- Extended unmanned operation

- Easy programming (no specialist robot programming knowledge required)

- Quick and trouble-free installation with less field assistance required

- Appropriate for both small and large batch sizes

- Automated robot cell for loading and unloading of workpieces

- Robot and stocker system can be easily moved (mounted on a common base plate)

- Unhindered access for manual intervention, manual operation and maintenance

- The TA and Machine combination are fully CE Marked by Mazak

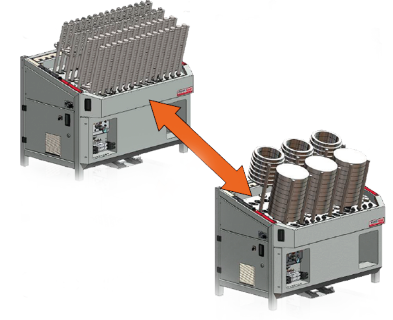

- Flexible - Can be configured for billet or shaft work [OPTION]

Features

QUICK TURN 200MB with TA-12

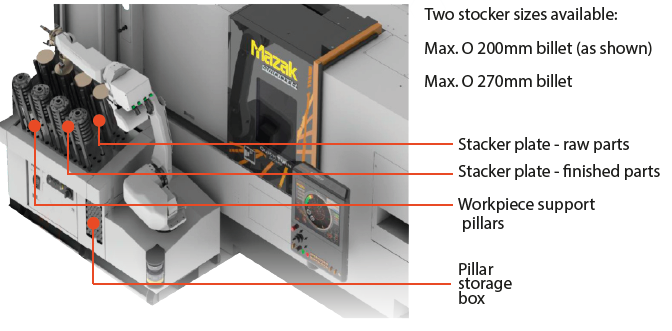

Stocker Unit

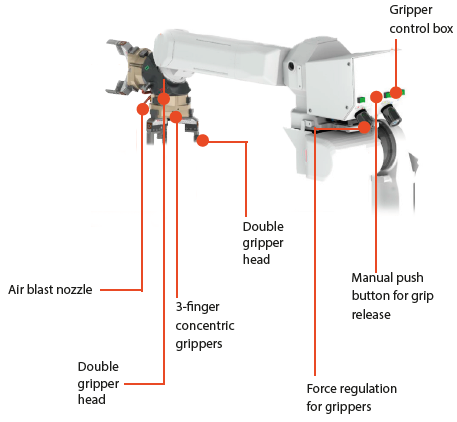

Gripper System

T

| Ø x length (mm) | No. of pieces |

| 40 x 20 | 510 |

| 80 x 30 | 224 |

| 150 x 35 | 50 |

| 200 x 35 | 40 |

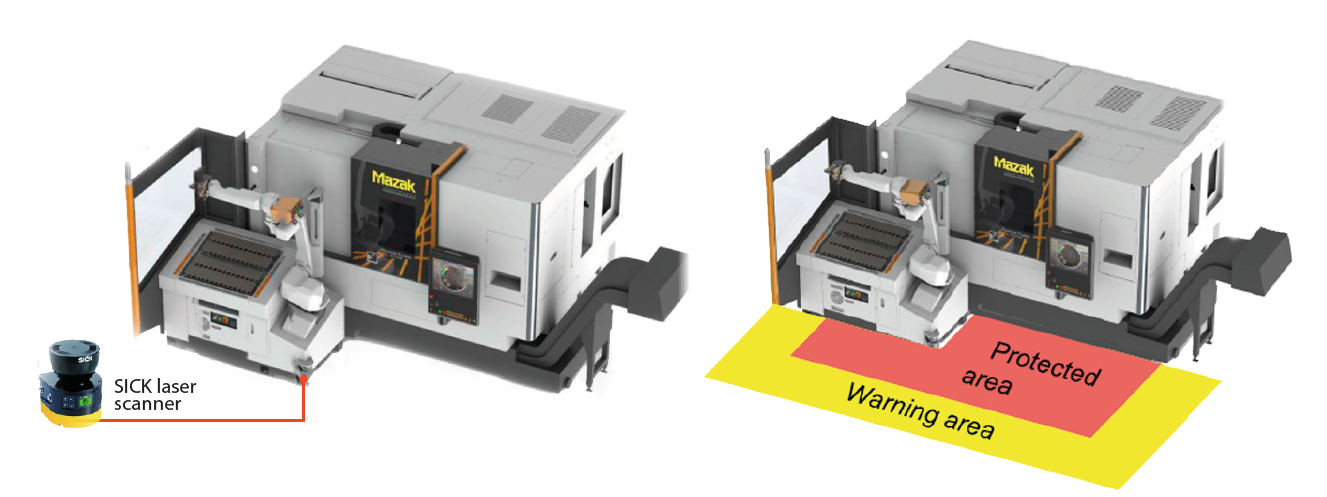

Guarding

- Guarding is minimal and features a steel and acrylic screen on two sides and by a SICK microScan3 Core Safety Laser Scanner on the other two sides

- This lack of conventional guarding coupled with an angled robot mounting base allows very easy and uncluttered access to the machine

- The TA and Machine combination are fully CE Marked by Mazak

Warning area - audible warning signal given if entered and robot slows to 10% of the programmed speed

Protect Area - the robot will stop immediately if entered

Graphical User Interface

GUI integrated into SmoothG controller

- Provides a seamless interface for the operator with the same look and feel

- Simple to use

- Parametric style entry of data

- Extremely fast set-up & programming (possible within 5 minutes)

- Unique TA series OEM automation package

- Reduced cost due to combined control system and power supply for both machine and robot

- Alternative retrofit automation solutions require separate robot controllers and cannot offer the same advantages

Applicable Machines

| TA Models | Machine |

|---|---|

| TA-12/200, TA-20/200, TA-20/270 |

QUICK TURN 200MB, 200MY, 200MS, 200MSY, 250MB, 250MY, 250MS, 250MSY, 300MSY, 350, 350MA, 350MB, 350MS, 350MSY, 350MY |

| TA-35/270 |

QUICK TURN 200MB, 200MY, 200MS, 200MSY, 350MB, 350MY, 350MS, 350MSY |

QUICK TURN 250MY and TA-12, a ‘plug and play’ turning centre and robotic machine tending solution designed to appeal to customers requiring a single source supplier for both machine tool and automation.

Watch VideoComplete machining of an electric drive coupling on a Mazak QUICK TURN 250MSY with TA-20/270 integrated robot cell. This combination brings together advanced technology, productivity and value to deliver exceptional performance for shops of all sizes.

Watch VideoQUICK TURN 350MY with TA-35/270 automation system. High Performance for demanding workpiece applications. See it in action.

Watch Video